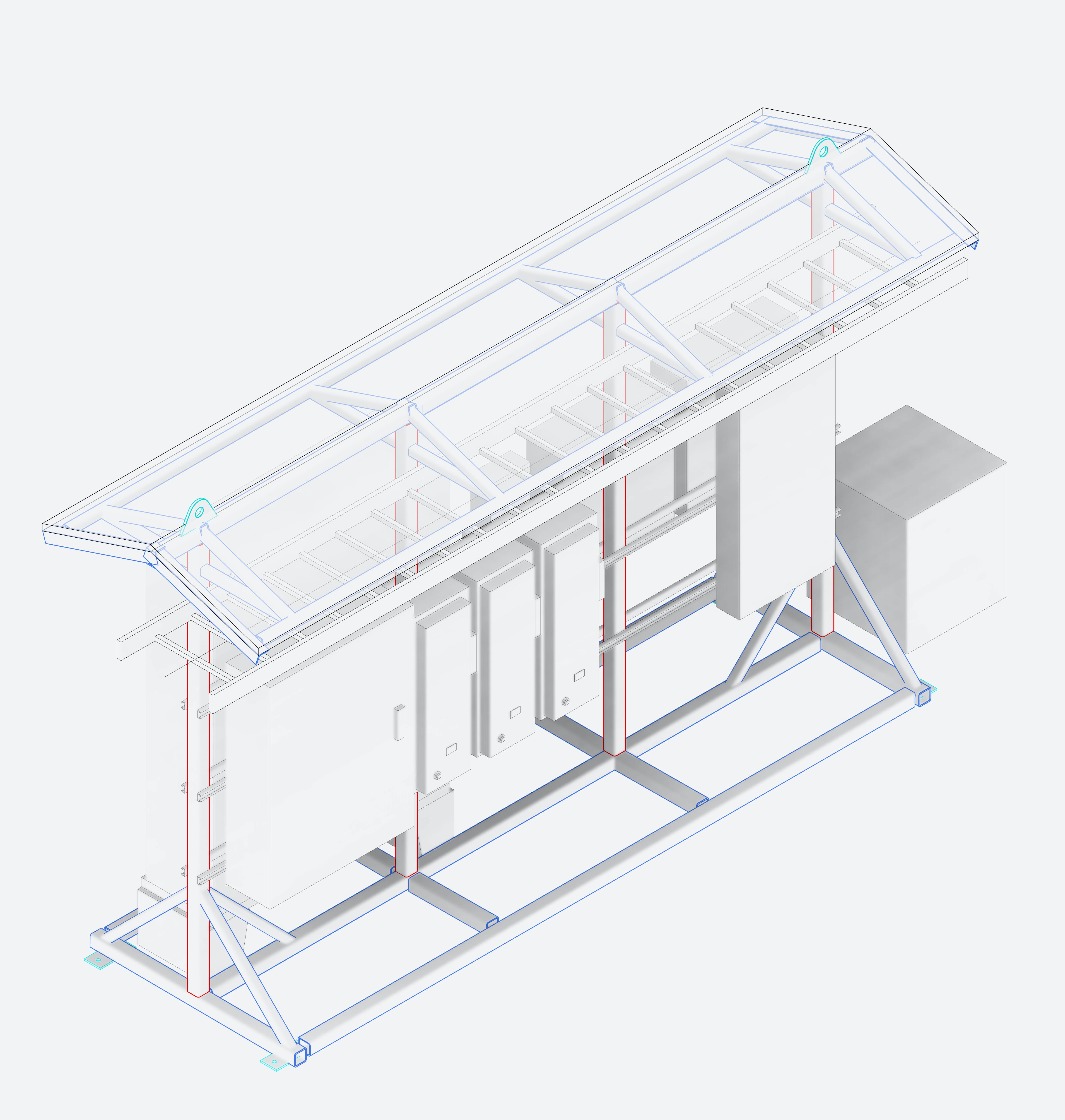

Ingenium has provided a variety of modular designs on projects. This request has ranged from small pipe racks and electrical racks all the way up to larger several story structures. Usually the goal with this delivery method is that a structure can be erected quickly with minimal to no onsite welding.

In the mining and power generation industry minimizing shutdown time is critical. Often times we only have a few days to completely erect, commission and hit the ground running. This may be the case with chutes, conveyors, or complete structures. Some equipment is mobile and needs to be relocated every year or even more frequently. We have designed overland conveyors on modular skids that can be extended and relocated as mining or disposal progresses.

We have also designed silos on a mobile skid that are to be moved as a conveyor is moved. This gave the client flexibility for locating these silos while also meeting permitting constraints.

Pipe racks were designed, fabricated and supplied by Ingenium for a dozen mining wells where they could be easily deployable at each of the sites in a systematic manner.

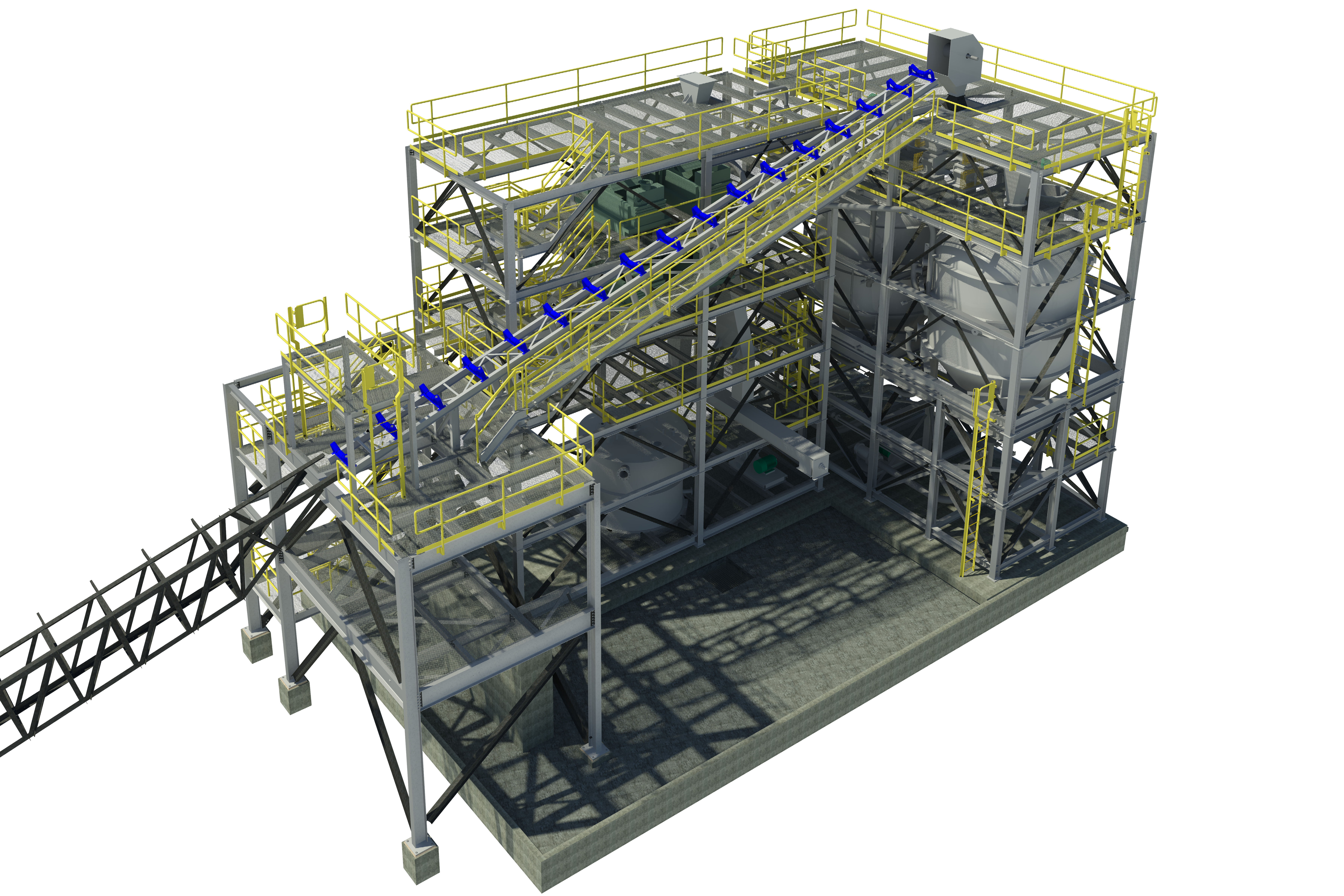

One larger structure was to be located where an existing process was located. The construction window was short because of the high altitude and harsh winter conditions, because of this the client wanted to build the whole structure out of modular sections. This presented a lot of challenges, because each of the modules supported different processing equipment. Including tanks, conveyors, chutes and piping. The modules all had access platforms and ladders that fit withing each of the modular sections. The structure was in a location where other major equipment was removed and the foundation was reused to save construction time.

We also have a large modular project in progress that we are excited about, but can’t talk about just yet. Check back for updates.

If you have a project that requires an out-of-the-box modular solution then you have arrived at the right place.