PNEUMATIC CONVEYING

FEEDER BELT DESIGN

DEM MODELING

LOADING AND UNLOADING

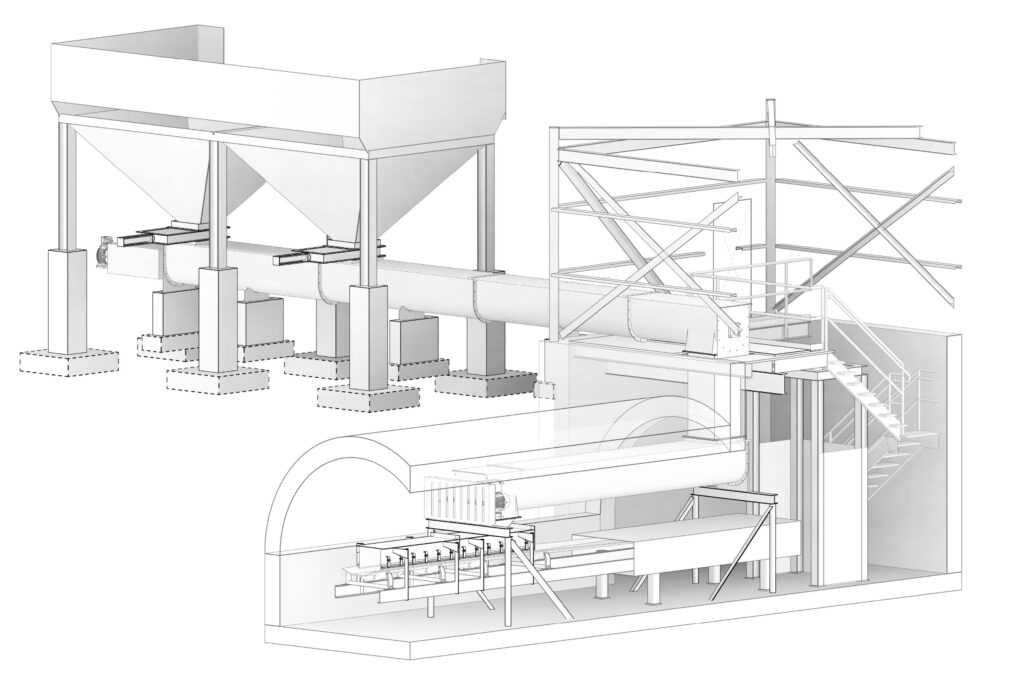

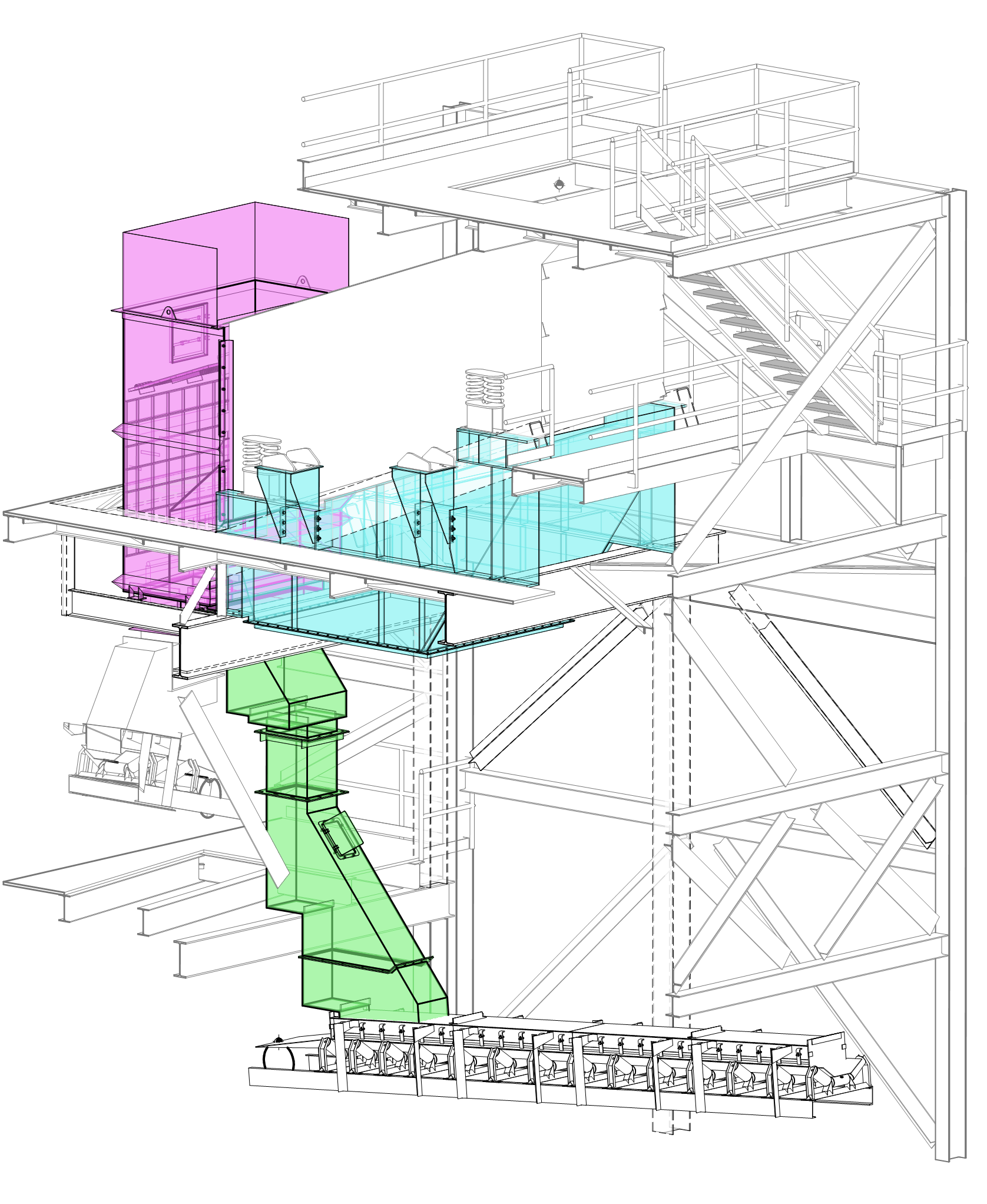

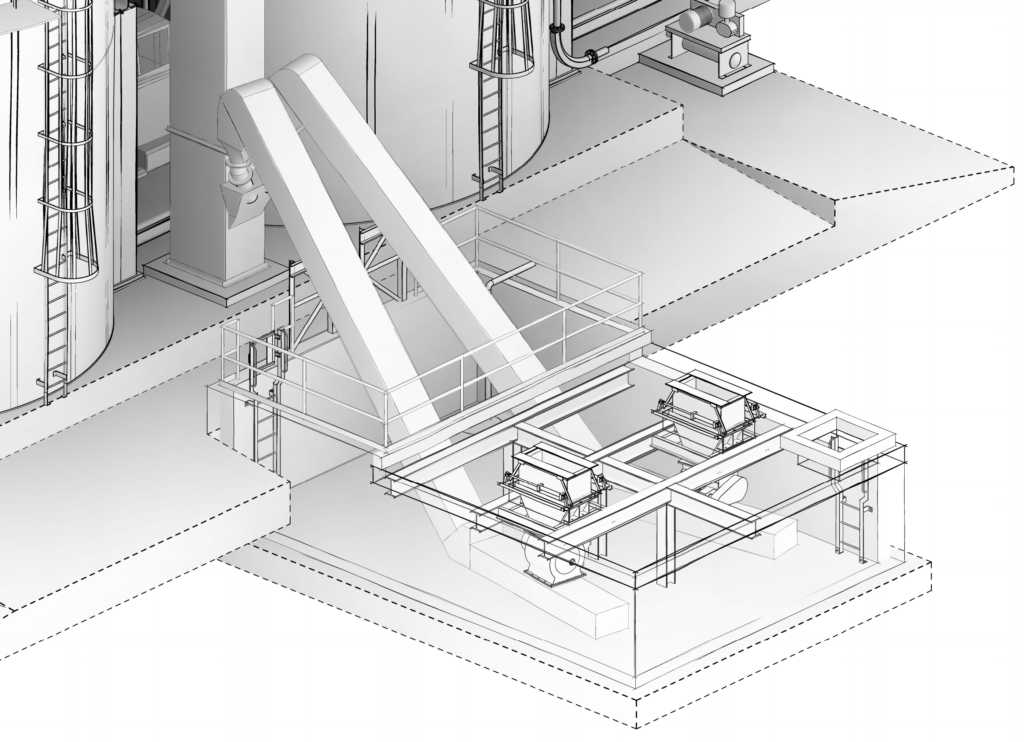

At the beginning of any project it is important to establish conveyor belt design requirements, conveyor capacity, belt speed, work-points and a general layout. This phase includes general arrangement drawings and a 3D model for client review. We can determine the critical interfaces with other material handling equipment and chute-work. If this work is part of an existing system or structure, we can create other 3D models of the existing structure and any potential interfaces, like a new conveyor. In our experience, a 3D model greatly reduces installation costs by avoiding interferences with existing structures or equipment at the very beginning. When complex geometry is not modeled, there tends to be expensive rework and down time that far exceeds the cost of creating a 3D model.

STORAGE FACILITIES

We provide comprehensive engineering services for the design, construction, and optimization of mining storage facilities. This includes the development of robust and efficient solutions for storing various types of minerals, ores, and concentrates. We evaluate factors such as material characteristics, storage volumes, environmental impacts, and seismic activity to determine the most suitable storage methods, including stockpiles, silos, and tanks. We conduct rigorous geotechnical and structural analyses to ensure the stability and safety of the storage structures and surrounding areas. We also implement advanced monitoring systems to track material inventories, detect potential hazards, and optimize storage operations.

CONVEYORS BENTS AND TRUSSES

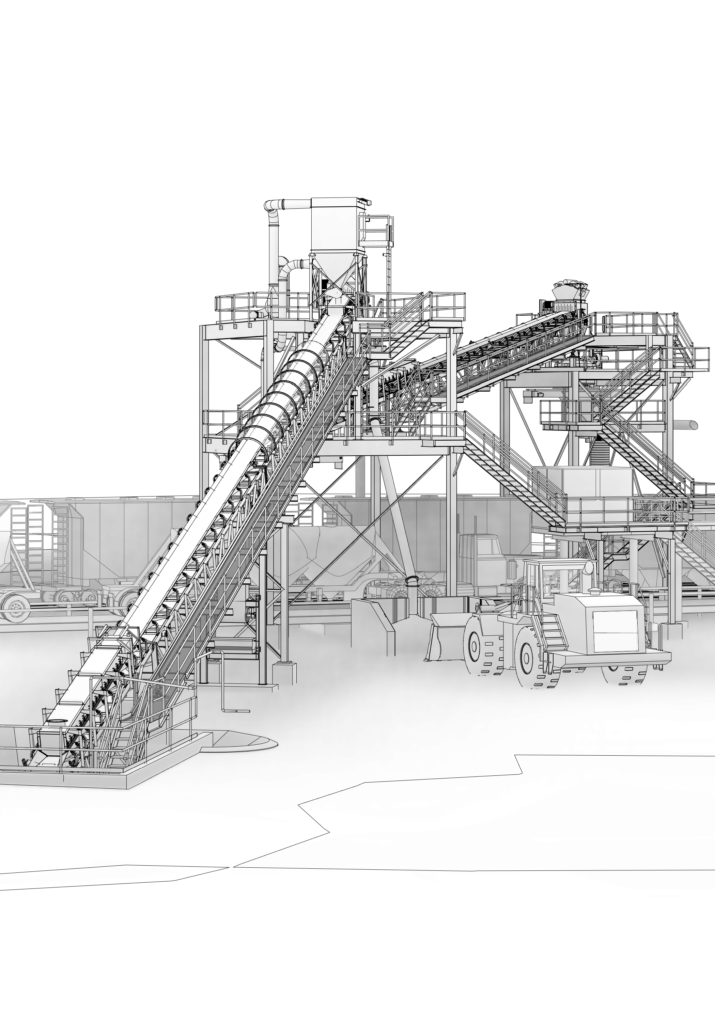

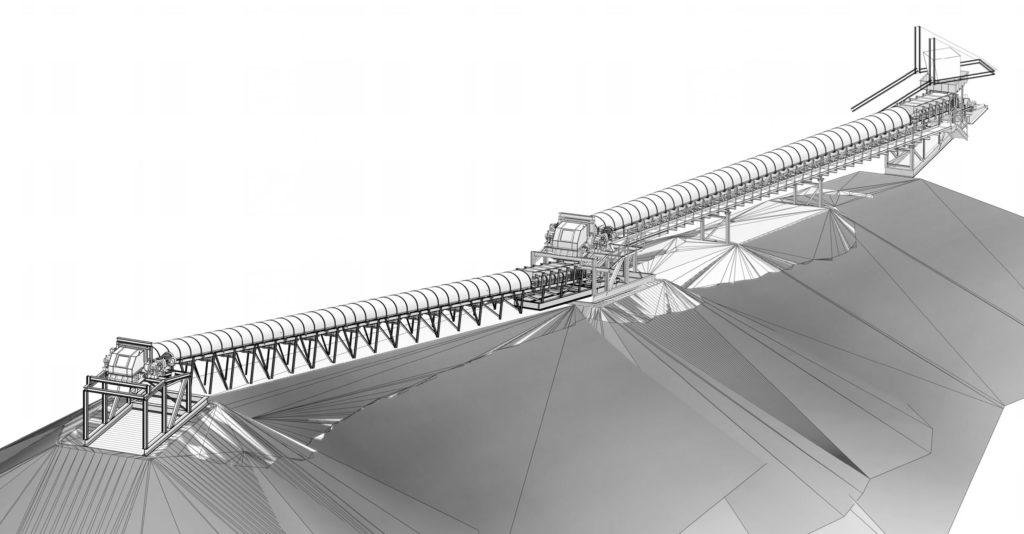

Conveyor belts are critical to transporting materials throughout a facility. Good conveyor design ensures that conveyors are reliable and can be safely maintained and operated. A well designed and properly installed conveyor increases productivity and profit, reduces downtime during operation, and most importantly increases the safety of your personnel.

Our experts have miles of conveyor belt design experience including long overland and enclosed tubular conveyors, elevated truss conveyors landing on 120-foot-tall stacking tubes or storage domes. We have designed rail dump hopper feeders with belt widths up to 72” inches, and reversed loadout conveyors. One project included five 60” wide conveyor belts and transfers within a single tower. We have also designed plants with dozens of conveyors snaking through facilities all thanks to our engineering experience and leading 3D modeling capabilities.

Basic Engineering Phase

At the beginning of any project it is important to establish conveyor belt design requirements, conveyor capacity, belt speed, work-points and a general layout. This phase includes general arrangement drawings and a 3D model for client review. We can determine the critical interfaces with other material handling equipment and chute-work. If this work is part of an existing system or structure, we can create other 3D models of the existing structure and any potential interfaces, like a new conveyor. In our experience, a 3D model greatly reduces installation costs by avoiding interferences with existing structures or equipment at the very beginning. When complex geometry is not modeled, there tends to be expensive rework and down time that far exceeds the cost of creating a 3D model.

This phase is highly collaborative in order to make all of the important decisions early in the design. A 3D model can be easily worked to present design decisions to the stakeholders, who can then make informed decisions with a 3D model, given it’s clear and understandable manner over its 2D counterpart. We understand that not all stakeholders will have the time to wrap their minds around hundreds or even thousands of 2D drawings and many stakeholders are not familiar with reading engineering drawings. This can make it difficult for stakeholders to make informed decisions and get the input from the people that matter. Once the 3D model is reviewed and approved, then detailed engineering can begin. Often times at the end of this phase, a preliminary cost estimate is established to begin setting project budgets.

Detailed Engineering Phase

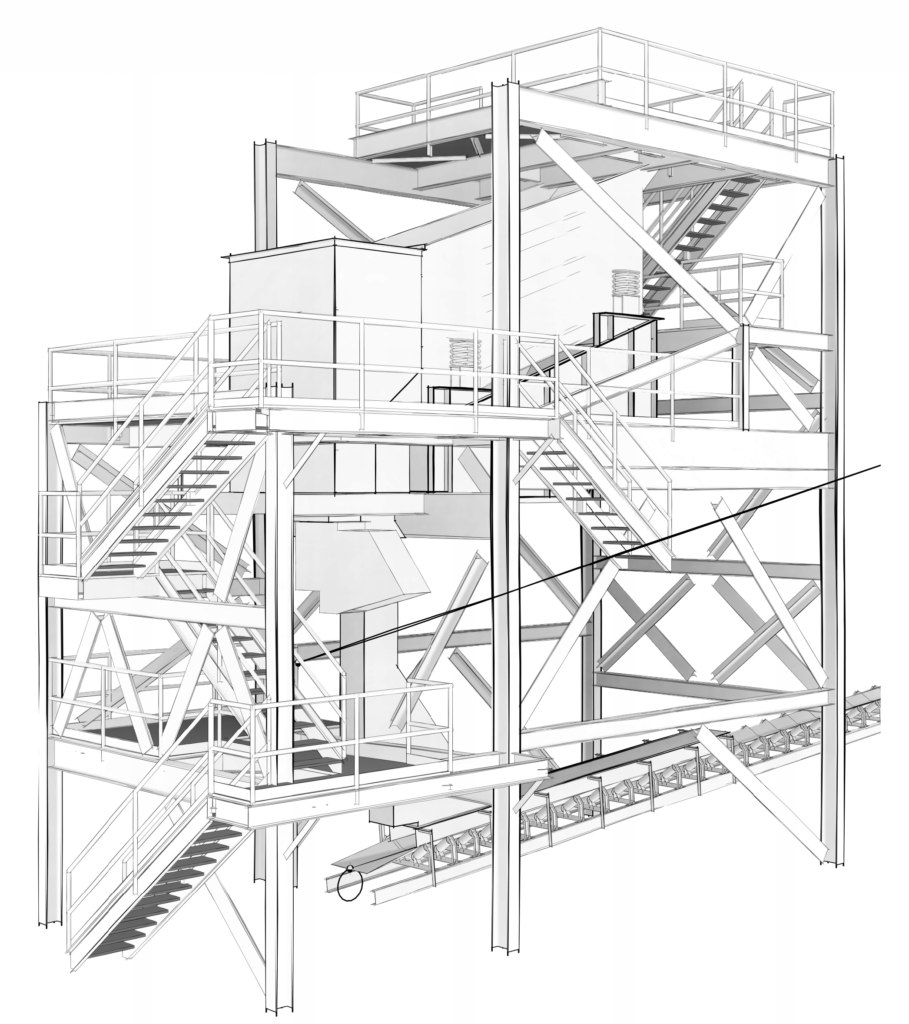

Design of the stringers, trusses, walkways, galleries, bents, towers, pulley frames, take-up carts, skirt boards, head-chutes all the way down to the foundations are provided in this stage. We would also love to design your transfer towers and can optimize these structures based on conveyor work-points and required transition distances.

Whether its helping you with the basic engineering phase, creating a 3D model, or just producing 2D drawings, we are happy to help at any stage of a project. Either way you will end up with a detailed 3D model with structural member sizes and accurately modeled conveyor components because our team of designers can model just as fast as they can draw. Ingenium Design can provide as much or as little scope as you need to get the job done right.

Procurement Assistance Phase

Conveyor components and steel are purchased either during or after the detailed engineering phase depending on the project timeline. If you need help purchasing the conveyor components, we will work with component vendors to get firm quotes that are ready for purchase to make sure technical requirements, part numbers, and quantities are correct.

You may have vendors you prefer for conveyor components. These can be incorporated into the design. If you need to go out for bid, for certain components, then we can help you through that process as well. The conveyor may require passive or active dust collection or suppression. These are systems our engineers can provide, more so than just the conveyor belt design.

We can also help with the bidding process. Here we provide bid evaluations and recommendations for vendors and steel fabricators. Ingenium Design will work closely with the steel detailer to ensure that all of the information from the detailed engineering phase gets communicated smoothly to detailers and fabricators. The 3D model developed in the engineering phase can greatly reduce the time required to detail and fabricate the steel. Many steel detailer’s can import our 3D model which contains the structural member sizes and other information they may need.

Project Approach and Delivery

Every project is different. That is why we work with you to find the best approach that makes sense for your site. We take into consideration installation from the very beginning to make sure that we can deliver a conveyor belt design that can be easily put into place. We continue to develop our designs and delivery methods as technology changes, and we have the flexibility to provide you exactly what you need on your next project.

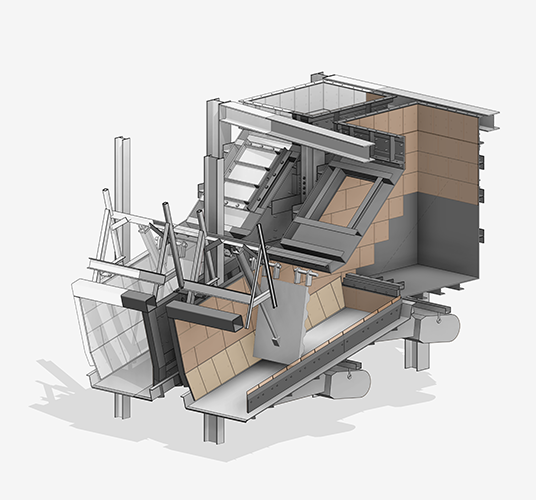

CHUTEWORK, HOPPERS & BINS

Chutework critically connects transfer points and equipment, reducing dust generation, abrasion and corrosion that can damage equipment and conveying systems. Finding the right geometry can become quite complex because it depends on the unique attributes of the material in transport, and the equipment that is being served. Ingenium Design’s standard operating procedure is to model all chutework in 3D so that every angle can be properly designed. Too many times chutework becomes an afterthought in bulk material handling design. This can lead to problematic chutes that plug, or wear out too fast. If you have chutework that is beyond it’s useful life or is giving you trouble and is covered in sledge hammer dents, let us help you design something that works.