COST ESTIMATING

GENERAL ARRANGEMENTS

SAFETY IMPROVMENTS

FACILITY EXPANSIONS AND EVALUATIONS

CAPITAL PROJECT LAYOUT

PROCUREMENT ASSISTANCE

INDUSTRIAL PLANT DESIGN

FACILITY EXPANSIONS & EVALUATIONS

Just because it’s old, doesn’t mean it needs replacing. Upgrading an existing installation can buy you additional years of operation, without large capital expenditures. However, knowing what the likely problems and costs are, is critical to making an informed decision. Sometimes you just need to know if it’s still safe.

We are well versed in evaluating a wide range of structures and mechanical equipment. From corroded towers, to deteriorating chutework, to malfunctioning dust collection, we will bring clarity and direction to your concerns—and give you honest answers.

Our evaluations range from a quick walk-through and brief report to an exhaustive field investigation coupled with thorough engineering calculations. Get in touch to discuss what the right option is for you.

MECHANICAL EVALUATIONS

We are experienced with:

- Belt conveyors

- Crushers, compactors, and screens

- Dust collection

- HVAC

- Pumps and piping

STRUCTURAL EVALUATIONS

We specialize in evaluating:

- Hoppers and bins

- Structural steel

- Concrete

- Vibration

- Fatigue and Fracture

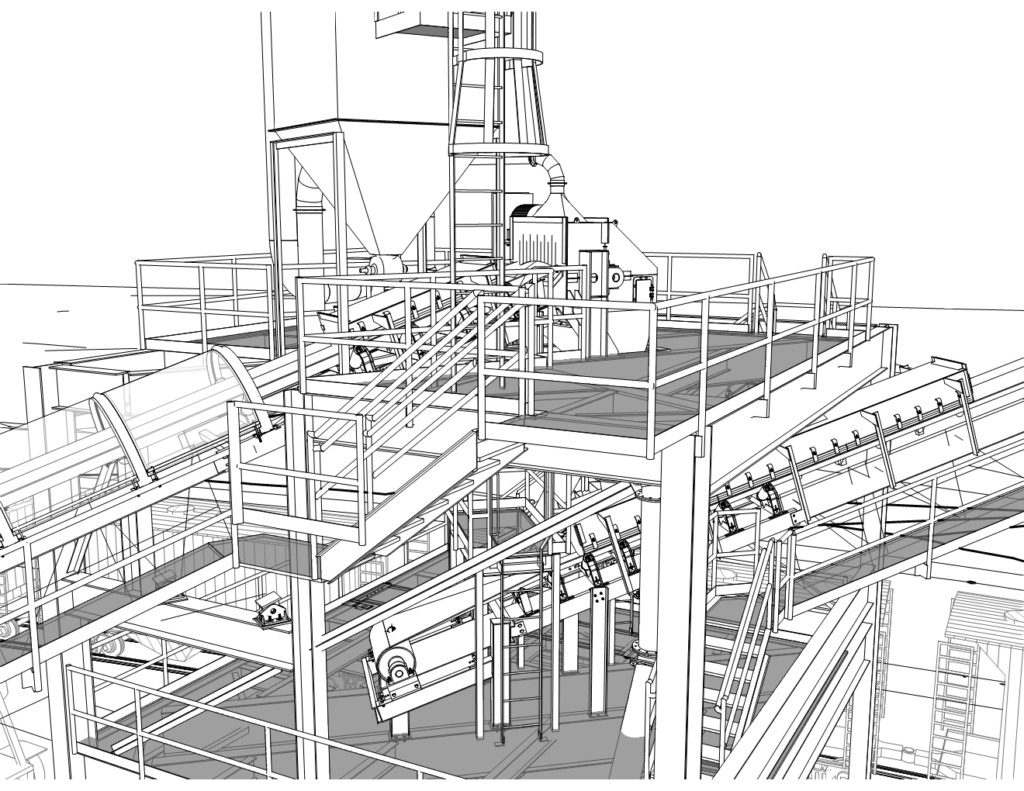

EXISTING INSTALLATIONS

Are your drawings missing? We are experienced in field measuring existing equipment, ductwork, piping, and structures. We take our field notes, and generate the information you need—drawings, 3D models…you name it.

EMERGENCY RESPONSE SERVICES

Has something gone terribly wrong? Do you need some extra man power and expertise to help you through it? Our experienced engineers have serious experience when it comes to fixing problems—on short notice.

OTHER DISCIPLINES

Do you need additional disciplines for your evaluation—like electrical or civil engineering, or non-destructive examination? We would be happy to team with one of our partners to bring you the complete evaluation solution

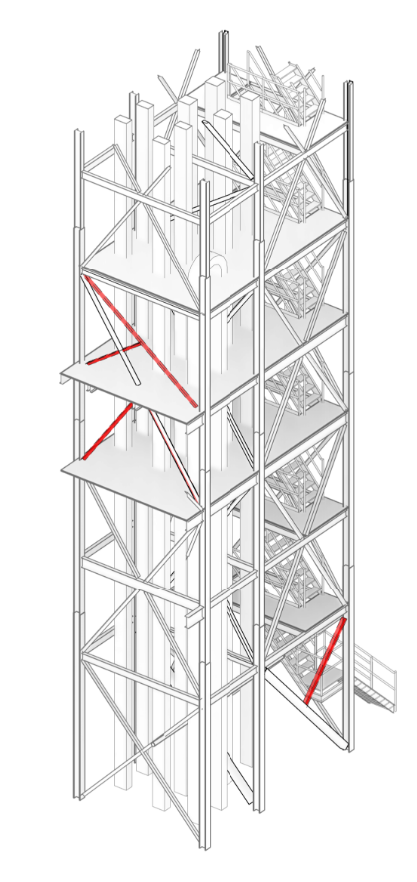

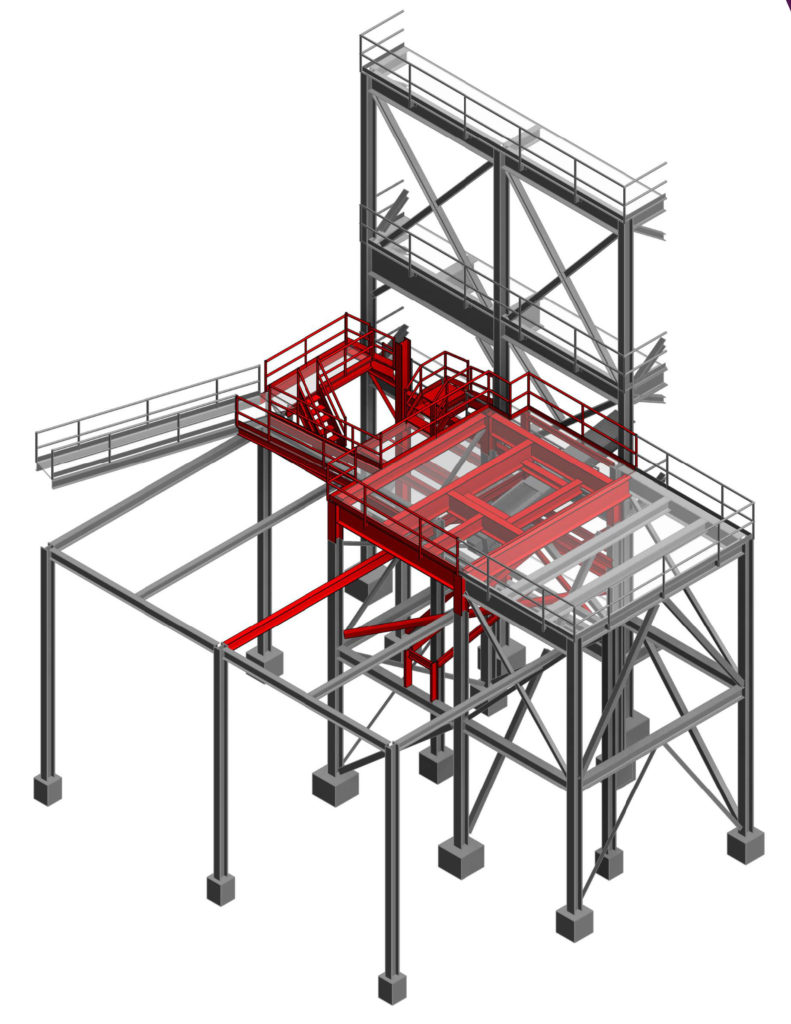

INDUSTRIAL PLANT DESIGN

Industrial plant design begins with a process, represented on a flow sheet. We then begin to model the equipment required to process and convey the material. Our best results come when this process is conducted with all the stake holders intimately involved. At Ingenium Design we utilize “War Room” sessions where everyone has input at key points as the design and model evolves. This allows the team to make critical decisions early in the process.

This collective brain makes more intelligent decisions and works through the constraints of each discipline. This results in a superior layout early on, and allows the customer to fully understand what their facility will do and look like. This approach reduces changes during design, fabrication and construction, process creating serious savings for the customer. We love the results we are having from this process and are confident you will too. Once the 3D model or General Arrangements are complete and vetted, detailed engineering begins and construction documents generated.

Don’t keep doing things the old fashioned way, work with us and see how enjoyable the design process can really be.