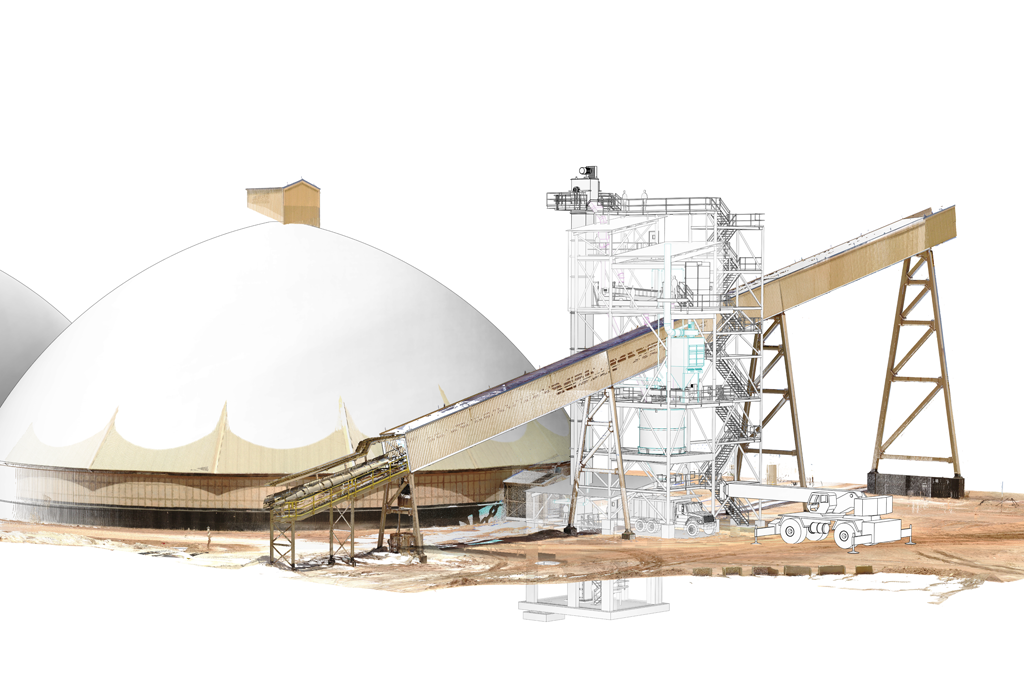

CONCEPT DESIGN

PRESENTATION PACKAGES & SITE RENDERS

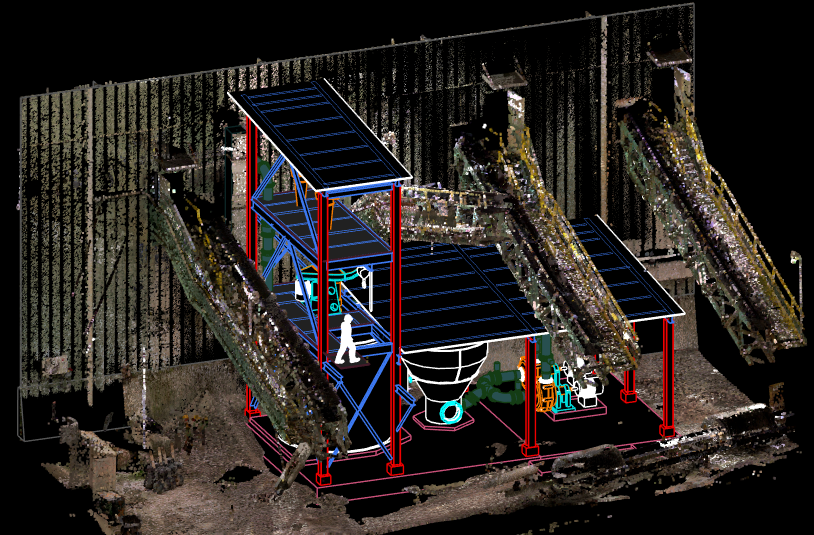

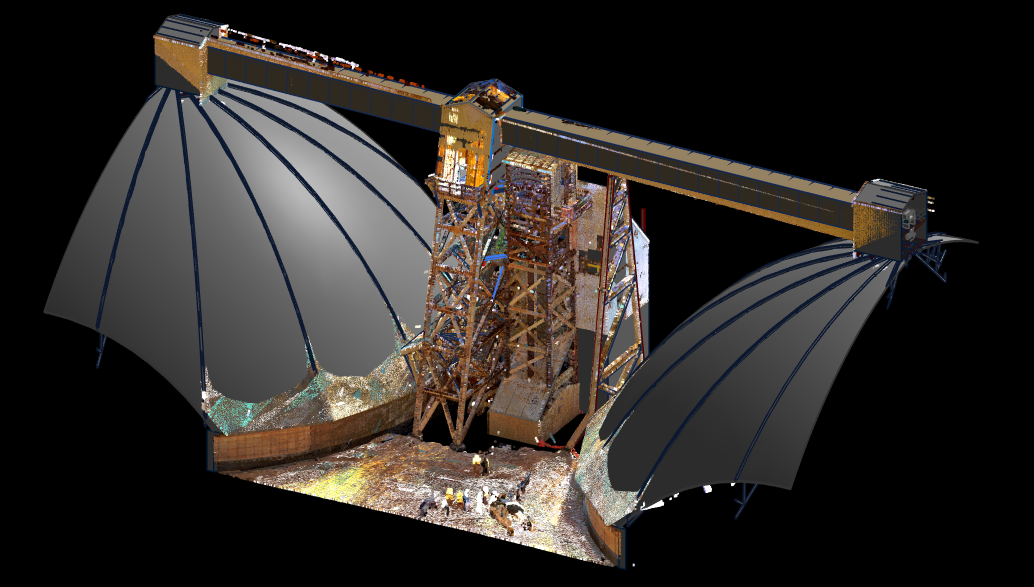

LASER SCANNING

Plants are often complex and difficult to navigate with pipes, beams, and equipment running everywhere. When replacing equipment, it can be difficult to know just how the new equipment will fit in. Normally that involves a few people, some tape measures, and hours spent in the field measuring. Using a laser scanner to generate a point cloud, this work is done more accurately in less time. Checking for interferences can be done at a whole new level. This means less field work, finger crossing, and mistakes.

The scanner works by sending out 500,000 laser beams per second in nearly every direction, recording the time it takes for them to hit an object. Using this information, the scanner generates millions of points with spatial information that can be compiled into a mass of points that represents the object reflecting the laser beams. With some post processing, these point clouds can be imported and used with other 3D software. Ingenium scans have are accurate up to 1/8″ for objects scanned withing 200 ft of the scanner. After the scan is complete, it takes a panoramic picture of the area just scanned, and assigns each laser point with a color. When the model is brought into a software for viewing, the realistic model it generates is better than any picture, and has the perks of being measurable. Laser scanning is good for:

Please reach out to us if you are interested in viewing a model so that we can send you a sample. For many projects these scanners save money, increase productivity, and eliminate errors. Let Ingenium Design create your next 3D model using their laser scanning technology.

- As Built Models

- Retrofit & Replacement

- Feasibility studies & expansion

- Complex geometry mapping (equipment, pipes, ducts)

- Hard to measure areas

- Existing structure documentation

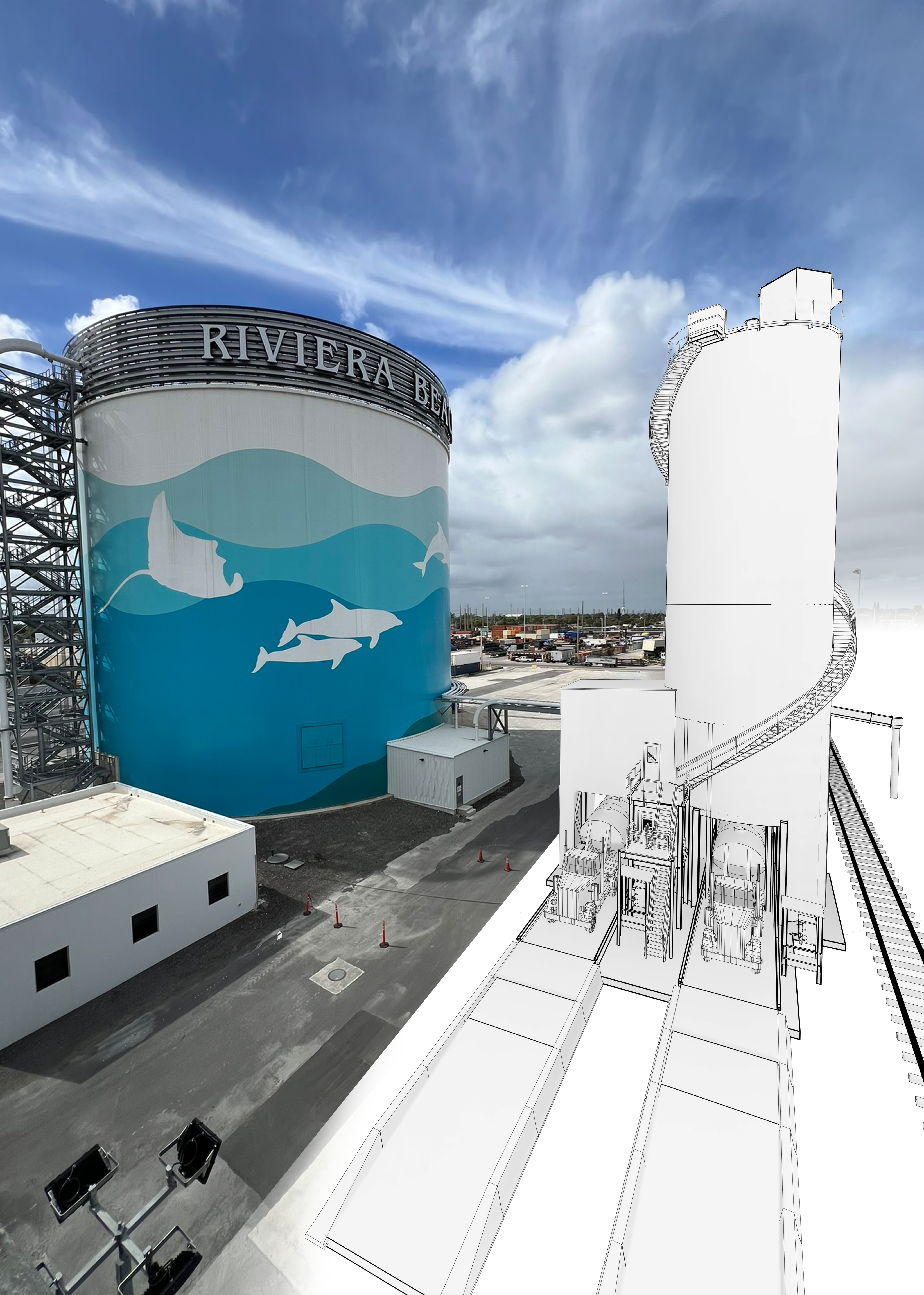

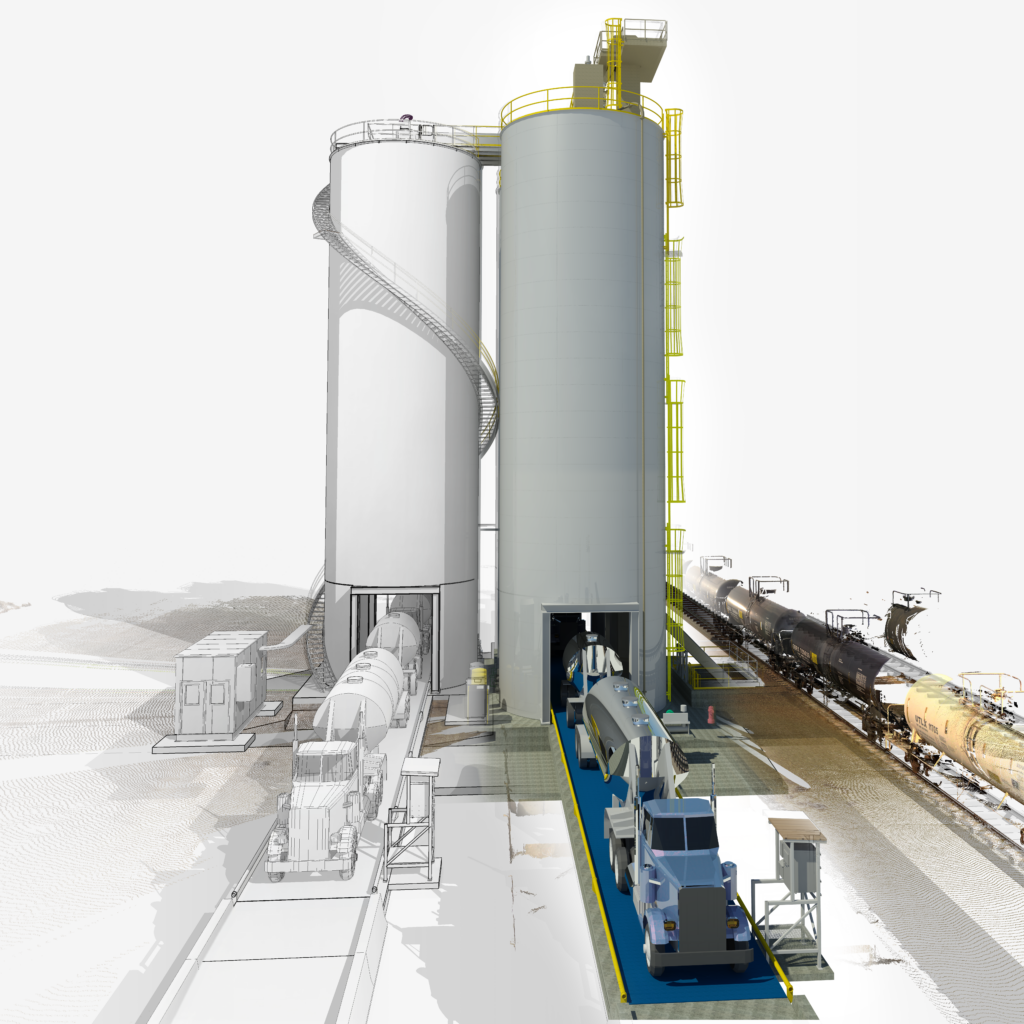

3D MODELING

At Ingenium Design we put a lot of emphasis on 3D modeling. We can not express enough that “out of sight, out of mind” really represents a lack of clear communication. A 3D model clearly communicates to all the engineering disciplines, designers, fabricators, contractors and the end user what the final product should look like. We understand that not everyone involved in a project has the time or know-how to study and understand all the engineering drawings for each discipline. The 3D model presents the information in a clear way and is really our primary communication tool during the design process. Once the 3D model is defined well enough to communicate the information critical to the project, then engineering drawings are made.

We can provide as-built 3D models for existing facilities where we collect existing drawings and field information. The 3D model can be used to design upgrades and retrofits with a much better understanding of what challenges you may run into with your project. Providing the 3D model in the engineering phase can save time and money in the detailing/fabrication phase since the 3D model can be shared with the detailer.

Often times the geometry is complex in facilities and this is especially true with existing facilities. The 3D model simplifies decision making in a project and allows the project team to see multiple options quickly. Well informed decisions help move the project forward along a superior path and can prevent costly rework. This efficient design approach allows the appropriate amount of time to be spent on review of maintenance and safety associated with the project. These reviews allow for creative improvements to the design that can be very beneficial to the maintenance personnel and operators. The 3D model also gives an opportunity to bring in stakeholders that are not intimately familiar with the project. They can see the project progress and quickly see if there are any issues they observe prior to the project being installed. This observation or buy-in from additional stakeholders has proven to be useful in eliminating surprises or missed opportunities.

If you just want to make sure something will fit before you a pursue a project then give us a call. We can measure up your project’s interfaces and make an accurate model of what your idea will look like. This will give you the confidence you need to move the project forward without committing too much cost.

We give you clear graphical information, and there is no substitute. In the last decade, 3D modeling has become the standard. We are doing things on industrial projects that BIM never dreamed of. You will see your project long before the shovel hits the dirt.

We take the preliminary model, turn it into the structural model, and link it to our design software.

- Rendering

- 3D Modeling

- Mechanical and Structural plans

- As bult drawings and models

- Revit Smart Family Design

- Plant Design

- Layouts and General Arrangements

- Design, and Drafting

- Virtual Walkthroughs

- Equipment Coordination

- As-Built Modeling

- Point Cloud Scan Integration

- Interference and Geometric Studies